Media Services

10 steps to achieve world-class manufacturing maintenance practices

Date: 2018-12-25 16:24:01

Lean maintenance cuts cost and improves production by minimizing downtime, here are 10 best practices to implement to a manufacturing operation.

Manufacturers worldwide know that Lean maintenance practices cut costs and improve production by minimizing downtime. But the reality is that for many US manufacturers, up to 90% of the maintenance they perform is conducted on a reactive rather than proactive basis. Some blame the age of their equipment, the absence of spare parts and the rapid pace of manufacturing.

But it is possible to implement production maintenance best practices, and doing so will save time and money while increasing production in the long run. Here are 10 steps you can follow to establish Lean maintenance best practices at your manufacturing operation:

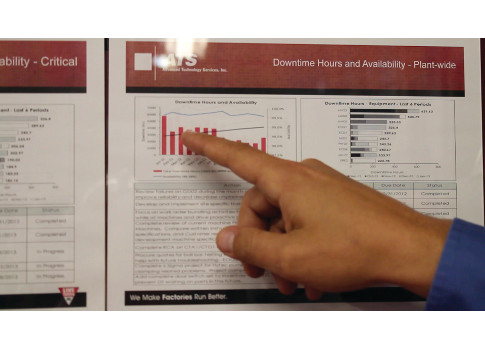

Step 1 – Gather data and calculate downtime costs. Before you can successfully transition to maintenance best practices, you’ll need to gather data to identify the scale of the challenge. Assemble information on machine downtime, meantime between machine failures, expenditures on parts, technology usage, technician response time and the percentage of on-time deliveries. This will enable you to calculate the average cost of one hour of downtime.

Step 2 – Determine the dollar value of maintenance. With an average per-hour downtime cost estimate in hand, you can project how much money maintenance improvements would save. You can make reasonable assumptions by applying the per-hour cost of downtime to machine availability, determining how much value an increase in availability will add to the organization. You’ll likely find that even a small increase, such as 5%, translates into a huge improvement.

Step 3 – Analyze operational variables. When determining projected productivity increases resulting from improved machine availability, it’s also important to factor in the savings your maintenance operation can realize by addressing operational variables. For example, take a look at how a better plan to handle critical spares, introduction of a work order system and faster technician response time could impact availability.

Step 4 – Invest in a technology solution. As you’ll see in step 3, controlling variables adds significant value, and a technology solution can make it easy to improve the handling of variables across the board. A Computerized Maintenance Monitoring System (CMMS) provides work order information and improves technician response time, also lowering the mean time to repair and reducing downtime overall.

Step 5 – Start scheduling preventive maintenance. With a CMMS that enables you to process work orders, you can easily monitor all manufacturing assets in your operation and track critical parts and spares. This means you’re ready to schedule preventive maintenance and generate checklists to manage maintenance tasks.

Step 6 – Deploy a scheduler planning function. As you transition from reactive maintenance to a more proactive stance, you’ll need to schedule technicians’ time for preventive maintenance and ensure that the right parts are available when needed. A scheduler planning function is a critical tool for reducing downtime and maximizing the value of preventive maintenance.

Step 7 – Introduce predictive tools. Preventive maintenance reduces downtime, and a predictive maintenance checklist can improve machine availability even more. The type of predictive tools you’ll need will depend on the equipment your team maintains. Electrical equipment can be hampered by overheating, so a thermography tool can prevent trouble before it results in downtime. Rotating equipment requires vibration analysis, and aircraft need ultrasound scanning for leaks.

Step 8 – Move toward Total Productive Maintenance (TPM). After the predictive maintenance plan is in place, the next step is to get operators involved in TPM. To leverage operators’ familiarity with manufacturing assets, find simple solutions that enlist operators in maintenance, such as keeping assets clean and freshly painted to aid in visual inspection or installing sight gauges that enable operators to monitor fluid levels.

Step 9 – Implement a Reliability Centered Maintenance (RCM) strategy. Once you have practices, technology and monitoring tools in place, you can begin practicing RCM to drive downtime to even lower levels. With a clearer view of machine capabilities and status, you no longer have to take equipment offline for preventive maintenance until your data indicates imminent failure. You can maximize value with a cost-benefit analysis of maintenance vs. productivity needs.

Step 10 – Bring in third-party technicians as needed. Achieving world-class maintenance involves a cultural transformation, and with a shortage of skilled technicians, it may be necessary to bring in third-party resources to establish metrics and define processes. If you are looking outside your company to achieve the cultural shift you require, make sure you get references from existing customers to ensure the right fit with your organization.

Deploying Lean maintenance practices takes analysis, planning and skill – but above all, it requires a commitment to move from a reactive to a proactive state of mind. By following these 10 steps, you can implement world-class maintenance practices at your manufacturing operation and significantly improve productivity.